INTRODUCTION

The HS2 project is one of the major underground works projects we have supported in the last few years.

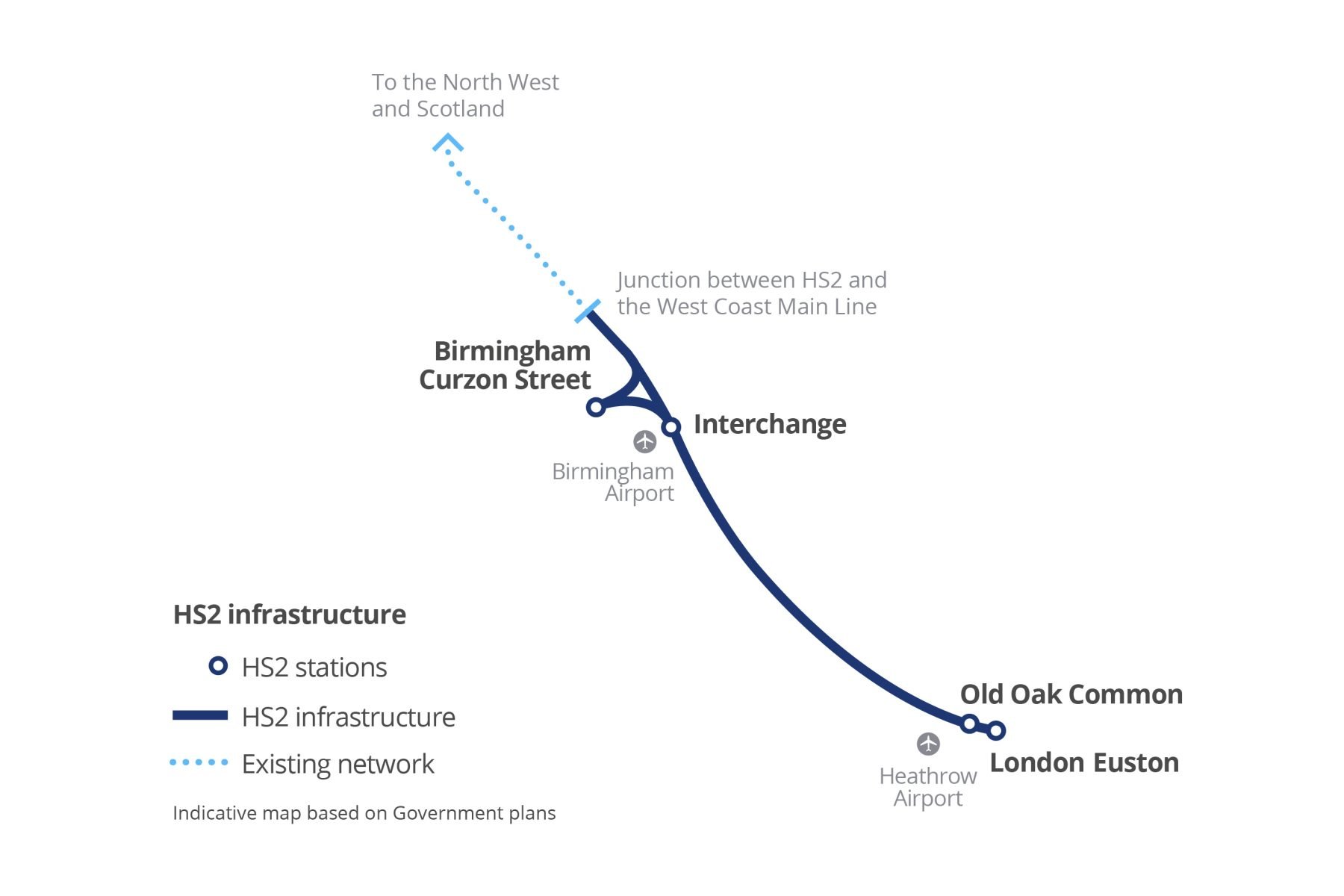

HS2 is a huge project which aims to link London and Birmingham by a high-speed train, reducing travelling time between the two cities by 40%.

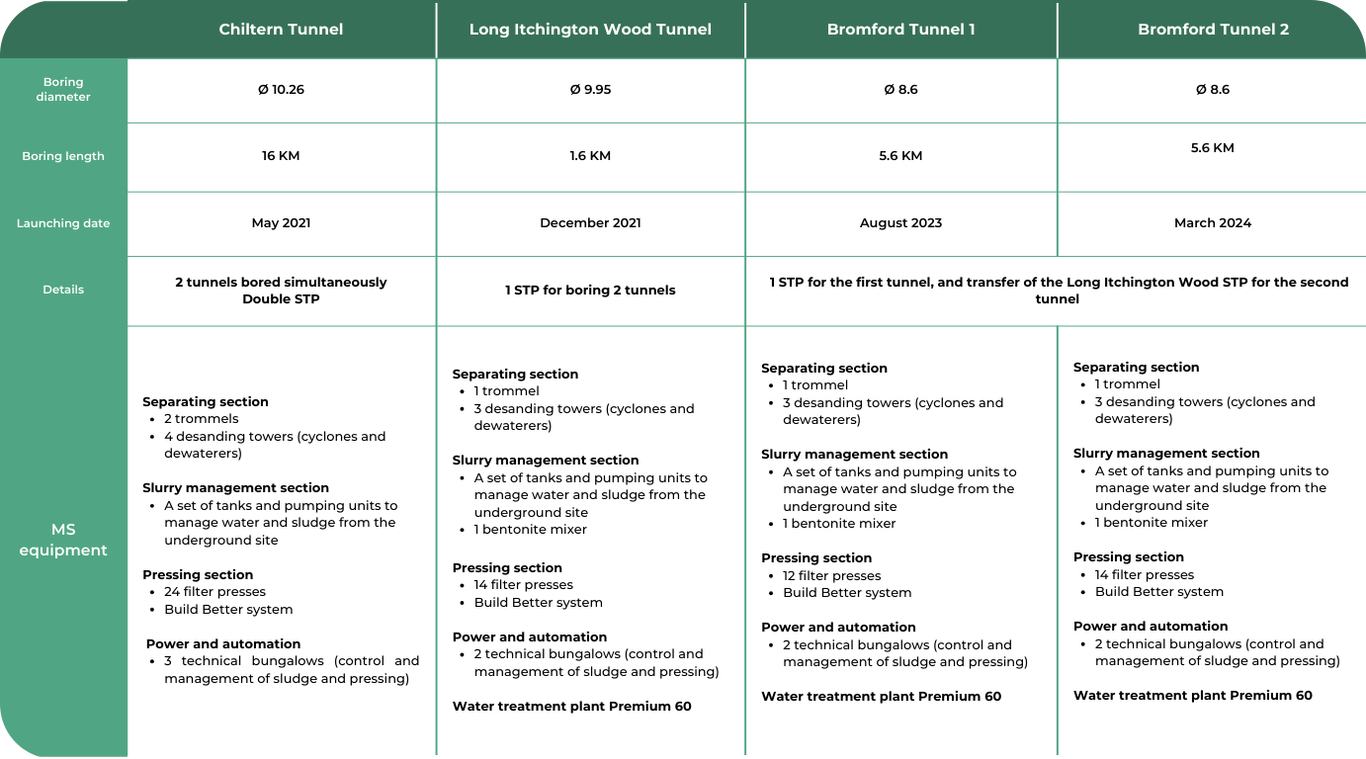

In 2019, Align JV (Joint-Venture of three international and private companies: Bouygues Travaux Publics; Sir Robert McAlpine, and VolkerFitzpatrick) has called on MS expertise in sludge and water treatment for the boring of the Chiltern double tunnel, the longest tunnel in the HS2 project (16 km).

Following this first project, BBV (a joint venture between Balfour Beatty and Vinci Construction) was able to see for itself our skills and expertise, which convinced them to call on us for two other tunnels in the HS2 project: the Long Itchington Wood Tunnel (1.6 km), and the Bromford Tunnel (5.8 km).

OUR SUPPORT

Our Slurry Treatment Plants (STP) have been designed to offer a complete and effective solution, perfectly adapted to the requirements of the worksite. Each section of the plants plays a key role in the treatment of the slurry and excavated materials:

- Separating section

This section is dedicated to extracting solids from the sludge. It includes trommels to remove the largest particles and desanding systems equipped with cyclones, which effectively separate the fine particles from the rest of the materials. The goal is to guarantee optimum quality sludge for reuse.

- Slurry management section

This part of the plant manages the storage and circulation of water and sludge from the TBM. It features tanks and pumps that enable the composition and rheology of the sludge to be adjusted in real time, which is essential for the stability and performance of boring operations.

- Pressing section

This section dehydrates excess sludge, reducing its volume and facilitating its removal. It uses filter presses to produce, with our Build Better device, solid sludge cakes with optimised productivity.

- Power and control

This section is used to supervise and manage operations. The technical bungalows monitor the performance of the various stages of treatment, adjusting parameters in real time and ensuring optimum coordination between the sections.

PROPOSED EQUIPMENTS

CHALLENGES AND PERFORMANCE.

In addition to the size of the project, HS2 is also a real technical challenge for several reasons:

First of all, the exceptional length of the Chiltern tunnel boring (16km) is in itself a huge challenge. Two 16km tunnels (32km of boring), representing 2,655,601 m3 of excavated earth, processed by our STP.

Secondly, the tunnel-boring geology, especially for the Chiltern Tunnel, is also a real challenge: mainly made up of chalk, this geology tends to completely disintegrate into extra-fine particles, specifically in slurry TBM methods.

Faced with this technical difficulty, the MS expertise in the management of extra fines was chosen. The 24 filter presses used during the boring of the Chiltern tunnels attained extraordinary productivity, due to the Build Better technology used.

RESULTS

Our collaboration with HS2 on the three tunnels, Chiltern, Long Itchington Wood and Bromford, has shown the effectiveness and suitability of our Slurry Treatment Plant (STP) in a wide variety of challenging environments.

Rob Cairns, HS2 Innovation Manager, said: ‘This brilliant innovation reduces the logistical operations involved in managing this waste, helping HS2 to achieve its ambition of reducing construction-related carbon emissions by 50%.’ By effectively treating the sludge and optimising its management, STP has made it possible to limit the associated transport, reducing both the carbon footprint and the logistical costs of each of the tunnels.

Moreover, hundreds of thousands of tonnes of excavated and dewatered waste found a second life: they were used to create 127 hectares of new habitats, contributing directly to HS2’s “green corridor” plans. This initiative reflects the project’s commitment to the environment and is part of a long-term sustainable strategy.

Thanks to an integrated approach suited to the specific characteristics of these tunnels, our support has made it possible to reconcile technical innovation, operational performance and respect for environmental objectives, while supporting the creation of modern and sustainable infrastructures